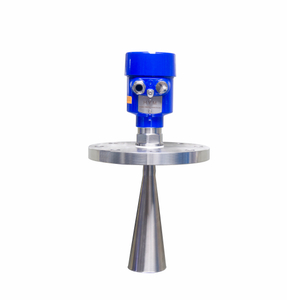

HWU30 Non-contact Ultrasonic Transmitter High Accuracy 4-20ma Integrated Ultrasonic Level Meter

| Availability: | |

|---|---|

| Quantity: | |

For non-contact continuous level measurement

When the measured liquid is vigorously stirred

When the measured liquid is viscous, sticky, film-forming or semi-solid

When measuring solids

When the tank is located in a remote area

Product Description:

High-Precision Measurement

The Non-contact Ultrasonic Transmitter offers exceptional accuracy in liquid level measurement, making it an invaluable tool for industries that require precise monitoring. Utilizing advanced ultrasonic technology, this integrated ultrasonic level meter measures liquid levels without physical contact, minimizing the risk of contamination and wear. This ensures a longer lifespan and reliable performance in various conditions.

Versatile Applications

Designed for a wide array of applications, the ultrasonic level meter is suitable for use in tanks, reservoirs, and wastewater treatment facilities. Whether you are in the manufacturing, food processing, or environmental sectors, this liquid level sensor provides accurate readings critical for efficient operations. Its versatility allows for seamless integration into existing systems, enhancing overall workflow.

Easy Installation and Maintenance

The installation process for the Non-contact Ultrasonic Transmitter is straightforward, requiring minimal effort and time. Its compact design ensures it fits in tight spaces, while the non-contact feature reduces maintenance needs, as there are no moving parts to wear out. This not only saves time but also reduces operational costs associated with maintenance and repairs.

Reliable Output and Data Transmission

Equipped with a 4-20mA output, this ultrasonic level meter provides a standard signal that can be easily integrated with most control systems. This feature enables real-time monitoring and data logging, allowing users to make informed decisions based on accurate liquid level measurements. With this reliable output, you can ensure consistent performance and operational efficiency.

Conclusion

Investing in the Non-contact Ultrasonic Transmitter means choosing a solution that combines high accuracy, versatility, and ease of use. Enhance your liquid level monitoring capabilities with this advanced technology, ensuring optimal performance in your operations.

FAQ

1. What is the measurement range of the Non-contact Ultrasonic Transmitter?

The transmitter typically measures levels from [insert specific range], making it suitable for various applications.

2. How does the non-contact feature benefit my operations?

The non-contact design reduces the risk of contamination and wear, ensuring accurate measurements and lower maintenance costs.

3. What types of liquids can this level meter measure?

It is suitable for a wide range of liquids, including water, chemicals, and wastewater.

4. Is the installation process complicated?

No, the installation is straightforward and can be completed quickly with minimal tools required.

5. Can I integrate this device with my existing monitoring system?

Yes, the 4-20mA output is compatible with most control systems, allowing for easy integration and data transmission.

For non-contact continuous level measurement

When the measured liquid is vigorously stirred

When the measured liquid is viscous, sticky, film-forming or semi-solid

When measuring solids

When the tank is located in a remote area

Product Description:

High-Precision Measurement

The Non-contact Ultrasonic Transmitter offers exceptional accuracy in liquid level measurement, making it an invaluable tool for industries that require precise monitoring. Utilizing advanced ultrasonic technology, this integrated ultrasonic level meter measures liquid levels without physical contact, minimizing the risk of contamination and wear. This ensures a longer lifespan and reliable performance in various conditions.

Versatile Applications

Designed for a wide array of applications, the ultrasonic level meter is suitable for use in tanks, reservoirs, and wastewater treatment facilities. Whether you are in the manufacturing, food processing, or environmental sectors, this liquid level sensor provides accurate readings critical for efficient operations. Its versatility allows for seamless integration into existing systems, enhancing overall workflow.

Easy Installation and Maintenance

The installation process for the Non-contact Ultrasonic Transmitter is straightforward, requiring minimal effort and time. Its compact design ensures it fits in tight spaces, while the non-contact feature reduces maintenance needs, as there are no moving parts to wear out. This not only saves time but also reduces operational costs associated with maintenance and repairs.

Reliable Output and Data Transmission

Equipped with a 4-20mA output, this ultrasonic level meter provides a standard signal that can be easily integrated with most control systems. This feature enables real-time monitoring and data logging, allowing users to make informed decisions based on accurate liquid level measurements. With this reliable output, you can ensure consistent performance and operational efficiency.

Conclusion

Investing in the Non-contact Ultrasonic Transmitter means choosing a solution that combines high accuracy, versatility, and ease of use. Enhance your liquid level monitoring capabilities with this advanced technology, ensuring optimal performance in your operations.

FAQ

1. What is the measurement range of the Non-contact Ultrasonic Transmitter?

The transmitter typically measures levels from [insert specific range], making it suitable for various applications.

2. How does the non-contact feature benefit my operations?

The non-contact design reduces the risk of contamination and wear, ensuring accurate measurements and lower maintenance costs.

3. What types of liquids can this level meter measure?

It is suitable for a wide range of liquids, including water, chemicals, and wastewater.

4. Is the installation process complicated?

No, the installation is straightforward and can be completed quickly with minimal tools required.

5. Can I integrate this device with my existing monitoring system?

Yes, the 4-20mA output is compatible with most control systems, allowing for easy integration and data transmission.

Measuring range | 0~25m(customized) |

Blind area | 0.25~0.5m |

Accuracy | 0.25~0.5% |

Resolution | 1mm |

Working Pressure | Below 4 atmospheres |

Display | LCD display,show level height and spatial distance |

Analog output | 4~20mA,0~10V,0~5V etc |

Digital output | RS485 Modbus |

Power supply | DC24V,AC220V(built-in lightning protection) |

Ambient temperature | -20°C~+60°℃(high temperature customized) |

Electrical connection | M18*1.5 |

Process connection | Thread (G2 Default) or Flange. |

Probe material | ABS,PVC, PTFE optional |

Transmitter housing material | ABS; Aluminum alloy(for explosion-proof type) |

Protection grade | IP68 |

Explosion proof | Ex d ia IIC T6 Gb |

Measuring range | 0~25m(customized) |

Blind area | 0.25~0.5m |

Accuracy | 0.25~0.5% |

Resolution | 1mm |

Working Pressure | Below 4 atmospheres |

Display | LCD display,show level height and spatial distance |

Analog output | 4~20mA,0~10V,0~5V etc |

Digital output | RS485 Modbus |

Power supply | DC24V,AC220V(built-in lightning protection) |

Ambient temperature | -20°C~+60°℃(high temperature customized) |

Electrical connection | M18*1.5 |

Process connection | Thread (G2 Default) or Flange. |

Probe material | ABS,PVC, PTFE optional |

Transmitter housing material | ABS; Aluminum alloy(for explosion-proof type) |

Protection grade | IP68 |

Explosion proof | Ex d ia IIC T6 Gb |

For non-contact continuous level measurement

When the measured liquid is vigorously stirred

When the measured liquid is viscous, sticky, film-forming or semi-solid

When measuring solids

When the tank is located in a remote area

Product Description:

High-Precision Measurement

The Non-contact Ultrasonic Transmitter offers exceptional accuracy in liquid level measurement, making it an invaluable tool for industries that require precise monitoring. Utilizing advanced ultrasonic technology, this integrated ultrasonic level meter measures liquid levels without physical contact, minimizing the risk of contamination and wear. This ensures a longer lifespan and reliable performance in various conditions.

Versatile Applications

Designed for a wide array of applications, the ultrasonic level meter is suitable for use in tanks, reservoirs, and wastewater treatment facilities. Whether you are in the manufacturing, food processing, or environmental sectors, this liquid level sensor provides accurate readings critical for efficient operations. Its versatility allows for seamless integration into existing systems, enhancing overall workflow.

Easy Installation and Maintenance

The installation process for the Non-contact Ultrasonic Transmitter is straightforward, requiring minimal effort and time. Its compact design ensures it fits in tight spaces, while the non-contact feature reduces maintenance needs, as there are no moving parts to wear out. This not only saves time but also reduces operational costs associated with maintenance and repairs.

Reliable Output and Data Transmission

Equipped with a 4-20mA output, this ultrasonic level meter provides a standard signal that can be easily integrated with most control systems. This feature enables real-time monitoring and data logging, allowing users to make informed decisions based on accurate liquid level measurements. With this reliable output, you can ensure consistent performance and operational efficiency.

Conclusion

Investing in the Non-contact Ultrasonic Transmitter means choosing a solution that combines high accuracy, versatility, and ease of use. Enhance your liquid level monitoring capabilities with this advanced technology, ensuring optimal performance in your operations.

FAQ

1. What is the measurement range of the Non-contact Ultrasonic Transmitter?

The transmitter typically measures levels from [insert specific range], making it suitable for various applications.

2. How does the non-contact feature benefit my operations?

The non-contact design reduces the risk of contamination and wear, ensuring accurate measurements and lower maintenance costs.

3. What types of liquids can this level meter measure?

It is suitable for a wide range of liquids, including water, chemicals, and wastewater.

4. Is the installation process complicated?

No, the installation is straightforward and can be completed quickly with minimal tools required.

5. Can I integrate this device with my existing monitoring system?

Yes, the 4-20mA output is compatible with most control systems, allowing for easy integration and data transmission.

Measuring range | 0~25m(customized) |

Blind area | 0.25~0.5m |

Accuracy | 0.25~0.5% |

Resolution | 1mm |

Working Pressure | Below 4 atmospheres |

Display | LCD display,show level height and spatial distance |

Analog output | 4~20mA,0~10V,0~5V etc |

Digital output | RS485 Modbus |

Power supply | DC24V,AC220V(built-in lightning protection) |

Ambient temperature | -20°C~+60°℃(high temperature customized) |

Electrical connection | M18*1.5 |

Process connection | Thread (G2 Default) or Flange. |

Probe material | ABS,PVC, PTFE optional |

Transmitter housing material | ABS; Aluminum alloy(for explosion-proof type) |

Protection grade | IP68 |

Explosion proof | Ex d ia IIC T6 Gb |

Quick Links

Product Category

Contact Us

Phone : +86-17551075580

E-mail : info@hjsensor.com

Whatsapp : +8617551075580