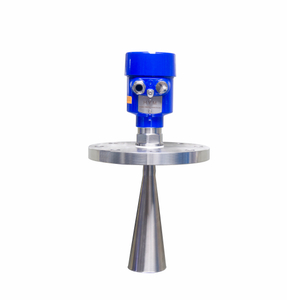

HWU32 Wall-Mounted Split Typle Ultrasonic Water Liquid Level Meter 24VDC 220VAC

| Availability: | |

|---|---|

| Quantity: | |

Applications

For non-contact continuous level measurement

When the measured liquid is vigorously stirred

When the measured liquid is viscous, sticky, film-forming or semi-solid

When measuring solids

When the tank is located in a remote area]

Features

Adopt advanced microprocessor and unique Echo Discovery processing technology, suitable for various complicated working conditions

The "false echo learning " function can correctly confirm the real echo and obtain accurate measuring result.

The built-in temperature sensor in the transducer can achieve the temperature compensation for measurement value.

Adopt the best acoustic configuration patented technology to improve signal intensity to achieve accurate measurement.

FAQ

1. What is the measurement range of the Non-contact Ultrasonic Transmitter?

The transmitter typically measures levels from [insert specific range], making it suitable for various applications.

2. How does the non-contact feature benefit my operations?

The non-contact design reduces the risk of contamination and wear, ensuring accurate measurements and lower maintenance costs.

3. What types of liquids can this level meter measure?

It is suitable for a wide range of liquids, including water, chemicals, and wastewater.

4. Is the installation process complicated?

No, the installation is straightforward and can be completed quickly with minimal tools required.

5. Can I integrate this device with my existing monitoring system?

Yes, the 4-20mA output is compatible with most control systems, allowing for easy integration and data transmission.

Applications

For non-contact continuous level measurement

When the measured liquid is vigorously stirred

When the measured liquid is viscous, sticky, film-forming or semi-solid

When measuring solids

When the tank is located in a remote area]

Features

Adopt advanced microprocessor and unique Echo Discovery processing technology, suitable for various complicated working conditions

The "false echo learning " function can correctly confirm the real echo and obtain accurate measuring result.

The built-in temperature sensor in the transducer can achieve the temperature compensation for measurement value.

Adopt the best acoustic configuration patented technology to improve signal intensity to achieve accurate measurement.

FAQ

1. What is the measurement range of the Non-contact Ultrasonic Transmitter?

The transmitter typically measures levels from [insert specific range], making it suitable for various applications.

2. How does the non-contact feature benefit my operations?

The non-contact design reduces the risk of contamination and wear, ensuring accurate measurements and lower maintenance costs.

3. What types of liquids can this level meter measure?

It is suitable for a wide range of liquids, including water, chemicals, and wastewater.

4. Is the installation process complicated?

No, the installation is straightforward and can be completed quickly with minimal tools required.

5. Can I integrate this device with my existing monitoring system?

Yes, the 4-20mA output is compatible with most control systems, allowing for easy integration and data transmission.

Measuring medium | Liquid |

Accuracy | 0.25%~0.5% |

Measuring Range | 5m,10m,15m, 20m, 25m |

Blind zone | 0.25m~0.6m |

Process Connection | G1 thread, Flange |

Shell Material of Energy Converter | PTFE, PVC,ABS |

Ambient temperature | -30℃ ~ +60℃ (Please specify special high and low temperature environment customization) |

Working pressure | Below 4 atmospheres |

Analog output | 4-20mA |

Digital output | RS485 Modbus protocol or custom protocol |

Power supply voltage | DC24V/AC220V,lightning protection device built-in |

Resolution of ranging | 1mm |

Working pressure | Below 4 atmospheres |

Display | LCD(Show liquid level or space distance) |

Probe signal cable length | 10meter |

Protection grade | IP65 or IP68 |

Measuring medium | Liquid |

Accuracy | 0.25%~0.5% |

Measuring Range | 5m,10m,15m, 20m, 25m |

Blind zone | 0.25m~0.6m |

Process Connection | G1 thread, Flange |

Shell Material of Energy Converter | PTFE, PVC,ABS |

Ambient temperature | -30℃ ~ +60℃ (Please specify special high and low temperature environment customization) |

Working pressure | Below 4 atmospheres |

Analog output | 4-20mA |

Digital output | RS485 Modbus protocol or custom protocol |

Power supply voltage | DC24V/AC220V,lightning protection device built-in |

Resolution of ranging | 1mm |

Working pressure | Below 4 atmospheres |

Display | LCD(Show liquid level or space distance) |

Probe signal cable length | 10meter |

Protection grade | IP65 or IP68 |

Applications

For non-contact continuous level measurement

When the measured liquid is vigorously stirred

When the measured liquid is viscous, sticky, film-forming or semi-solid

When measuring solids

When the tank is located in a remote area]

Features

Adopt advanced microprocessor and unique Echo Discovery processing technology, suitable for various complicated working conditions

The "false echo learning " function can correctly confirm the real echo and obtain accurate measuring result.

The built-in temperature sensor in the transducer can achieve the temperature compensation for measurement value.

Adopt the best acoustic configuration patented technology to improve signal intensity to achieve accurate measurement.

FAQ

1. What is the measurement range of the Non-contact Ultrasonic Transmitter?

The transmitter typically measures levels from [insert specific range], making it suitable for various applications.

2. How does the non-contact feature benefit my operations?

The non-contact design reduces the risk of contamination and wear, ensuring accurate measurements and lower maintenance costs.

3. What types of liquids can this level meter measure?

It is suitable for a wide range of liquids, including water, chemicals, and wastewater.

4. Is the installation process complicated?

No, the installation is straightforward and can be completed quickly with minimal tools required.

5. Can I integrate this device with my existing monitoring system?

Yes, the 4-20mA output is compatible with most control systems, allowing for easy integration and data transmission.

Measuring medium | Liquid |

Accuracy | 0.25%~0.5% |

Measuring Range | 5m,10m,15m, 20m, 25m |

Blind zone | 0.25m~0.6m |

Process Connection | G1 thread, Flange |

Shell Material of Energy Converter | PTFE, PVC,ABS |

Ambient temperature | -30℃ ~ +60℃ (Please specify special high and low temperature environment customization) |

Working pressure | Below 4 atmospheres |

Analog output | 4-20mA |

Digital output | RS485 Modbus protocol or custom protocol |

Power supply voltage | DC24V/AC220V,lightning protection device built-in |

Resolution of ranging | 1mm |

Working pressure | Below 4 atmospheres |

Display | LCD(Show liquid level or space distance) |

Probe signal cable length | 10meter |

Protection grade | IP65 or IP68 |