4 Types of Pressure Sensors

Views: 335 Author: Site Editor Publish Time: 2025-08-29 Origin: Site

What is A Pressure Transmitter?

A pressure transmitter is a device used to measure and convert pressure signals, commonly used as an industrial pressure sensor. Converting pressure signals into a standard electrical output enables accurate pressure monitoring and control. Pressure transmitters can be categorized into various types based on their operating principles and materials, including diffused silicon, single-crystal silicon, ceramic, and sapphire. These different types of pressure transmitters are widely used in their respective fields, providing important support and assurance for industrial production and scientific research.

What is the difference between a pressure sensor and a pressure transmitter?

A pressure sensor converts a pressure signal into an electrical output, while a pressure transmitter converts a pressure signal into a standard output for transmission to a remote location or connection to a control system.

The differences between pressure transmitters are primarily due to the use of different pressure cores as measuring elements. Therefore, their overall accuracy and performance are determined by the sensor.

Four common types of pressure transmitters:

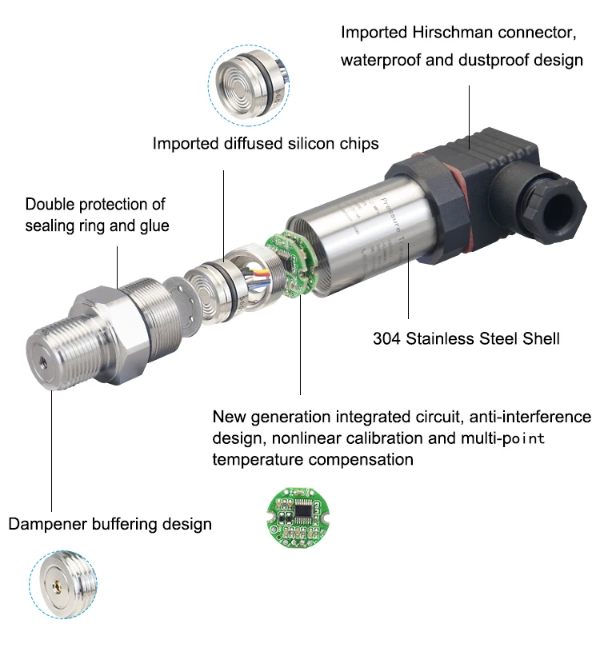

The diffused silicon pressure transmitter is the most common type, operating by utilizing the deformation of a silicon chip to measure pressure. Diffused silicon pressure transmitters offer high accuracy, excellent stability, and low cost, making them suitable for general industrial applications.

Monocrystalline silicon pressure transmitters are high-precision pressure sensors made from single-crystal silicon chips, offering enhanced sensitivity and stability. They are suitable for applications requiring high precision, such as aerospace and medical devices.

Ceramic pressure transmitters use ceramic as the sensing element, offering corrosion resistance and high-temperature resistance, making them suitable for pressure measurement in harsh environments. They are widely used in industries such as chemical, petroleum, and metallurgy.

Sapphire pressure transmitters are high-temperature and high-pressure pressure sensors made from sapphire, offering extremely high wear and corrosion resistance. They are suitable for high-temperature and high-pressure environments, such as aircraft engines and nuclear power plants.

How to Select the Right Pressure Transmitter?

When selecting the right pressure transmitter, consider the operating environment's characteristics, including the pressure range, temperature range, and media properties. Different types of pressure transmitters are suitable for different operating environments. For example, diffused silicon is suitable for general industrial applications, single-crystal silicon is suitable for high-precision applications, ceramic is suitable for harsh environments, and sapphire is suitable for high-temperature and high-pressure applications. Secondly, factors such as accuracy requirements, output signal type, and mounting method should be considered to ensure the selected pressure transmitter meets actual needs.

| Type | Accuracy | Allowable Working Pressure | Service/Application |

| Diffusion Silicon Pressure Transmitter | ±0.1%~±0.5% | -100Kpa...0~10Kpa...100Mpa | General industry |

| Monocrystalline Pressure Transmitter | ±0.075%~±0.2% | -4000Kpa~4000Kpa | High accuracy, differential pressure measuring, sealed tank liquid level |

| Ceramic Piezoresistive Pressure Transmitter | ±0.2%~±0.5% | -1bar~0...2bar...600bar | Corrosion medium |

| Ceramic Capacitive Pressure Transmitter | -100kpa...0~2.5kpa...7Mpa | ||

| Sapphire Pressure Transmitter | ±0.1%~±0.25% | 0... 700MPa | High-temperature and high-pressure environments |

What is the difference between a pressure transmitter and a pressure switch?

Although both pressure transmitters and pressure switches are devices used to monitor pressure, their operating principles and functions differ significantly. A pressure switch typically switches a circuit when a set pressure value is reached, thereby enabling start/stop control of the equipment. A pressure transmitter, on the other hand, converts the pressure signal into a standard electrical output for real-time monitoring and recording of pressure values. It is typically connected to a control system or data acquisition system for precise pressure control and monitoring.

Furthermore, a pressure switch typically has only two states—open and closed—for simple on/off control. A pressure transmitter, on the other hand, outputs a continuous pressure signal, enabling continuous pressure monitoring and regulation. Therefore, pressure transmitters are typically chosen when precise pressure monitoring and control are required, while pressure switches are preferred when simple on/off control is required. Both play an important role in industrial production, and it is crucial to select the appropriate device based on specific needs and application scenarios.

Should I choose a pressure transmitter or a pressure switch?

When selecting a pressure transmitter or pressure switch, you need to consider the specific application scenario and requirements. If real-time monitoring and precise control of pressure are required, a pressure transmitter is typically the right choice; if simple on/off control is all you need, a pressure switch is the right choice. Additionally, factors such as device reliability, stability, and maintenance costs should be considered to ensure the selected equipment can operate stably and meet production needs over the long term.

In summary, selecting the right pressure transmitter requires comprehensive consideration of factors such as the operating environment, accuracy requirements, and output signal type. When selecting a pressure transmitter or pressure switch, you need to consider the specific application and functional requirements to ensure the equipment can accurately and stably monitor and control pressure, improving production efficiency and product quality.

Summary

Before purchasing a product, it's important to understand the specifics of your industry, such as the measurement medium, operating pressure, and other factors.

We hope this article helps you understand more details. If you have further questions, please contact our sales team.