Related Videos

Welcome to HIGHJOIN! We are an enterprise dedicated to providing good performance pressure transmitters, committed to meeting the needs of various industries. We are well aware that in industrial applications, the reliability and accuracy of pressure monitoring are of vital importance. The pressure transmitters we provide are designed to ensure the safe operation and efficient performance of the equipment, helping customers optimize processes and enhance production efficiency. Whether in the fields of petroleum, chemical engineering or automation, our products can provide you with reliable solutions..

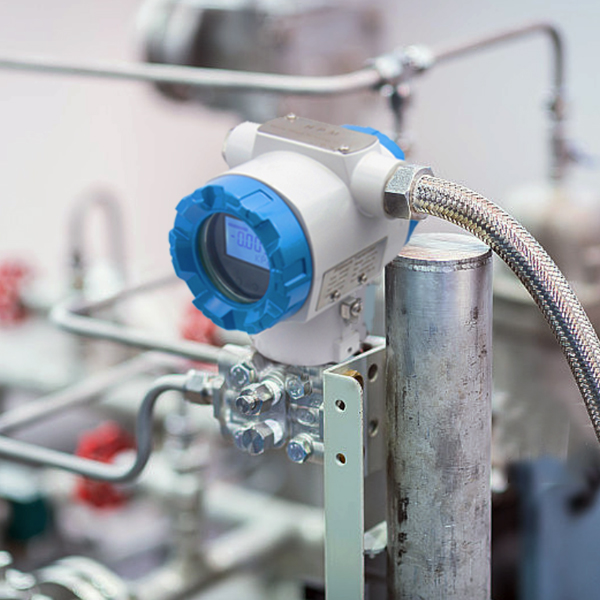

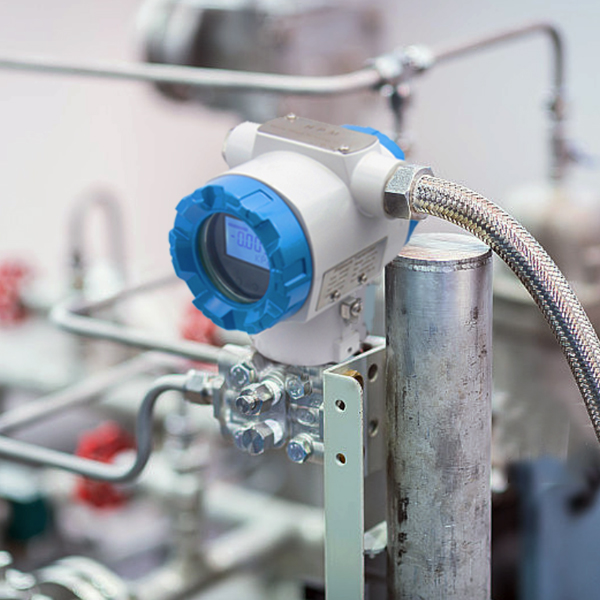

HPM87 Differential Pressure Transmitter

The HPM85 differential pressure transmitter accurately measures pressure differences in industrial applications for both liquids and gases. Its robust design and straightforward installation ensure reliability in harsh environments, while digital output allows seamless integration with control systems. Regular calibration and maintenance are essential for optimal performance, making the HPM85 a vital tool for effective pressure measurement.

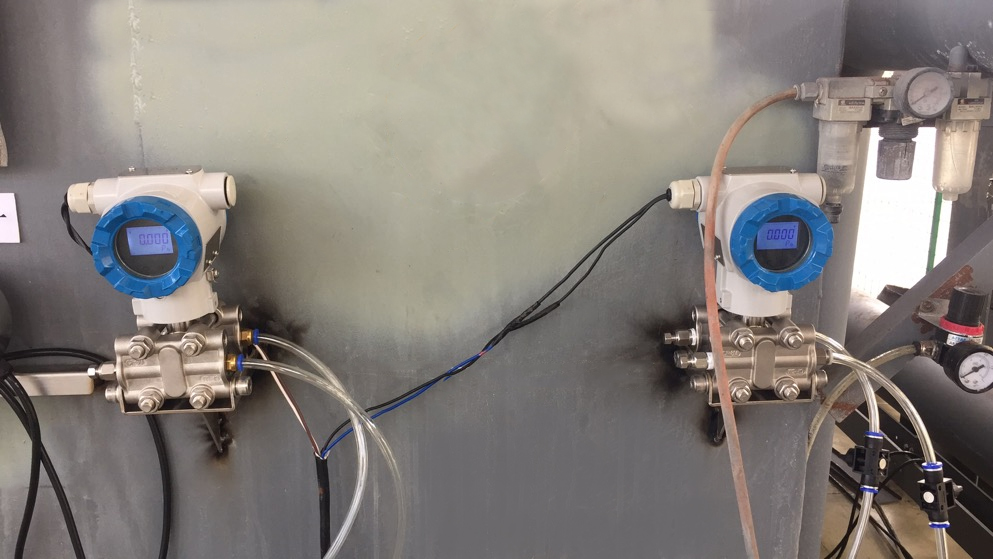

HS-DPS Differential Pressure Module

HS-DPS is a monocrystalline silicon module that customers can purchase separately and then assemble the whole machine.

The accuracy is ± 0.075%, the clamping plate is made of stainless steel, and it has an LCD on-site display.

Product Center

A Differential Pressure Transmitter (DPT) is a crucial device used in various industrial applications to measure the difference in pressure between two points, typically utilizing a 4-20mA current loop output or HART protocol. It plays a vital role in monitoring and controlling processes, ensuring safety and efficiency.

Related Certificate

ATEX, CNEX, ISO, CE, SIL, ROHS certificate for differential pressure transmitter.

Applications

Oil and Gas Industry

Pipeline Leak Detection: Differential Pressure Transmitters are essential for detecting leaks in pipelines and storage tanks. By monitoring pressure differences, they help identify abnormal conditions, ensuring safety and reducing losses.

Chemical Industry

Process Control:DPTs provide accurate measurements of pressure differentials critical for maintaining optimal chemical processes and reactions.

It aids in detecting pressure anomalies that could lead to dangerous situations, enhancing overall plant safety.

Engineering and Automation

Automated Control Systems:DPTs are integral to automated control systems that adjust fan speeds and airflow based on real-time pressure readings. This enhances overall system performance and energy efficiency, leading to reduced operating costs.

Level Measurement

DPTs accurately measure the level of liquids in tanks by gauging the pressure difference between the liquid surface and a reference point. Accurate level detection prevents overflows and maintains operational efficiency.

Product Advantages

Differential Pressure Transmitters (DPTs) has multiple advantages, including high-precision pressure difference measurement and a wide range of applications, such as level, flow and filter monitoring. They are durable and can operate stably in extreme environments, ensuring long-term reliability. Real-time monitoring capabilities enhance operational efficiency, promptly identify potential problems, reduce maintenance costs, and improve the overall system's security and economic benefits.

High Stability and Accuracy

Differential Pressure Transmitters normally adopts monocrystalline sensor, the accuracy can up to +/-0.075% to +/- 0.2%. This significantly enhances operational efficiency and the accuracy of process control through precise pressure difference measurement. They can continuously monitor pressure changes in the automated system, promptly identify potential problems, reduce faults and maintenance costs, and ensure long-term reliable operation.

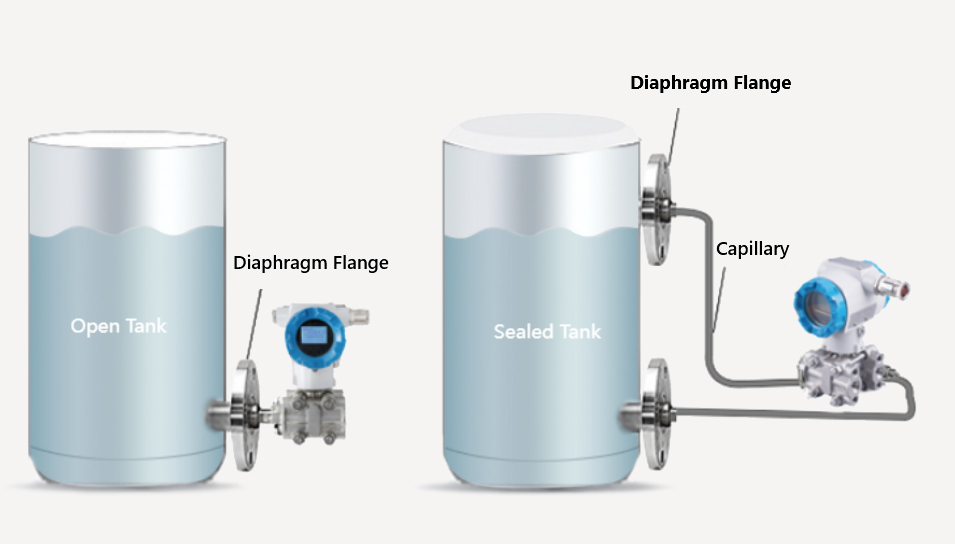

Differential Pressure Transmitter for Measuring Liquid Level

Differential pressure transmitters are widely used in various occasions, among which liquid level measurement is the most common application. Flange differential pressure transmitters can measure the liquid level of both open and closed tanks, which is crucial in multiple industries including water treatment and chemical manufacturing. By precisely monitoring the liquid level, these transmitters help prevent overflow and ensure the optimal operation of the equipment. Their sturdy design enables them to work effectively in harsh environments.

Differential Pressure Transducers for Explosion-Hazard Areas

Differential pressure transmitters are designed with safety in mind and can operate reliably in explosion-proof environments. CNEX, ATEX certificates are essential, which proves that they can be safely used in high-risk industries such as oil, gas and chemicals, ensuring safe operation and compliance with relevant industry standards.

Why Choose Us

15 Years Experience

With 15 years of experience, we have built a strong R&D team of industry experts and seasoned engineers. Our focus on research and development in lighting technologies allows us to consistently launch innovative products, ensuring we maintain a competitive edge in the market.

Demand Customization

We offer OEM/ODM services to meet the unique needs of our clients. Our goal is to tailor products to align perfectly with customer requirements, ensuring personalized solutions that enhance satisfaction and drive success.

Professional Solutions

We have developed pressure transmitters and temperature sensors integrated with intelligent control systems, capable of remote monitoring, data logging, temperature adjustment, and other functions, meeting the needs of automation process.

Quality Control and Management System

We implement strict quality control processes and have obtained international quality management system certifications such as ISO9001, ensuring that every product meets high-standard quality requirements.

FAQ

Q: What are the main applications of differential pressure transmitters?

A: Differential pressure transmitters are mainly used in industrial applications such as liquid level measurement, flow monitoring, filter status assessment and process control.

Q: How to choose the right differential pressure transmitter?

A: When making a selection, the measurement range, medium type, installation environment and the required output signal type should be taken into consideration.

Q: How to ensure the accuracy of differential pressure transmitters?

A: Regular calibration and maintenance are key to ensuring the performance and accuracy of the transmitter. It is recommended to operate in accordance with the manufacturer's instructions.

Keep in touch with us

Have questions about our Differential Pressure Transmitters or need a customized solution for your application? HJSensor is here to help! Our team of experts specializes in delivering high-precision pressure sensors for industries like oil and gas, manufacturing, and process control. Whether you’re seeking technical specifications, pricing, or tailored advice, we’re ready to assist.

Mob:+86-17551075580

Related Blogs

-

Radar level meters are commonly used in industrial applications for accurate and reliable level measurement of liquids, solids, and slurry in tanks and vessels. They are widely employed in industries such as oil and gas, chemical processing, and water treatment for monitoring storage levels, controlling processes, and ensuring operational safety. Radar level meters provide precise data for efficient inventory management and process optimization.Applications

Radar level meters are commonly used in industrial applications for accurate and reliable level measurement of liquids, solids, and slurry in tanks and vessels. They are widely employed in industries such as oil and gas, chemical processing, and water treatment for monitoring storage levels, controlling processes, and ensuring operational safety. Radar level meters provide precise data for efficient inventory management and process optimization.Applications -

Electromagnetic flowmeters are widely utilized in industrial applications for precise measurement of liquid flow rates. They are commonly used in industries such as water treatment plants for monitoring the flow of water and wastewater. Additionally, electromagnetic flowmeters find applications in industries like chemical processing, food and beverage, and pharmaceuticals for accurate flow measurement and process control.Applications

Electromagnetic flowmeters are widely utilized in industrial applications for precise measurement of liquid flow rates. They are commonly used in industries such as water treatment plants for monitoring the flow of water and wastewater. Additionally, electromagnetic flowmeters find applications in industries like chemical processing, food and beverage, and pharmaceuticals for accurate flow measurement and process control.Applications -

Differential pressure transmitters are used to measure the difference in pressure between two points in a system. They are commonly employed in industries such as HVAC, chemical processing, and oil and gas for monitoring flow rates, filter conditions, and level measurements. These transmitters provide accurate and reliable data for efficient system operation and maintenance.Applications

Differential pressure transmitters are used to measure the difference in pressure between two points in a system. They are commonly employed in industries such as HVAC, chemical processing, and oil and gas for monitoring flow rates, filter conditions, and level measurements. These transmitters provide accurate and reliable data for efficient system operation and maintenance.Applications