Level Measurement Solutions

· Submersible Level Transducer

· Radar Level Meter

The radar level gauge measures the liquid level by using microwave radar technology and features non-contact, high accuracy, and strong adaptability. Its working principle is to calculate the liquid level height by transmitting and receiving electromagnetic waves and measuring the propagation time of the waves. The radar level gauge is not affected by factors such as temperature, pressure, and steam, and is suitable for measuring various complex liquid and solid media. Due to its corrosion resistance and high-temperature resistance, radar level gauges are widely used in industries such as petroleum, chemical engineering, and power, and perform particularly well under high-temperature and high-pressure working conditions. In addition, the radar level gauge is easy to install and has low maintenance requirements, providing great convenience for users.

· Ultrasonic Level Meter

An ultrasonic level gauge is a device that measures liquid levels by using ultrasonic technology. Its working principle is to determine the liquid level height by emitting ultrasonic signals and receiving reflected waves, calculating the propagation time of the signals. Ultrasonic level meters have the advantage of non-contact measurement and are suitable for various liquid and solid media. They perform particularly well in the fields of sewage treatment and liquid storage. This equipment is easy to install, flexible to use, highly adaptable, and is not affected by the density, temperature or pressure of the liquid. However, ultrasonic level gauges may be subject to interference in environments such as steam, foam and strong winds, so these factors need to be taken into consideration when making a selection.

· Float Liquid Level Switch

The float switch is a simple yet effective liquid level control device, widely used in liquid storage equipment such as water tanks and oil tanks. Its working principle is to utilize the float ball to move up and down as the liquid level changes, triggering the switch to act, thereby achieving automatic control of the liquid level. The float switch has the advantages of simple structure, convenient installation, and low cost, and is suitable for liquid level monitoring of various liquids. Although its accuracy is relatively low, it can still meet the basic liquid level control requirements in many situations. The float switch has high reliability and can operate stably in harsh environments; thus, it has been widely applied in industries such as urban water supply and sewage treatment.

· Magnetic Flap Level Gauges

A magnetic flap level switch is a high-precision liquid level measurement device, usually used for liquid level monitoring in liquid storage tanks. Its working principle is that the magnetic float ball floats in the liquid, driving the flip of the flap to display the liquid level status. Magnetic flap level switches have the advantages of simple structure, no power demand, and high reliability. They are suitable for measuring various liquids, including corrosive liquids. This device not only provides continuous liquid level indication but also can be linked with the control system to achieve automatic control. Due to their high-temperature resistance and corrosion resistance, magnetic flap level switches are widely used in industries such as chemical engineering, petroleum, and food, providing users with safe and reliable liquid level monitoring solutions.

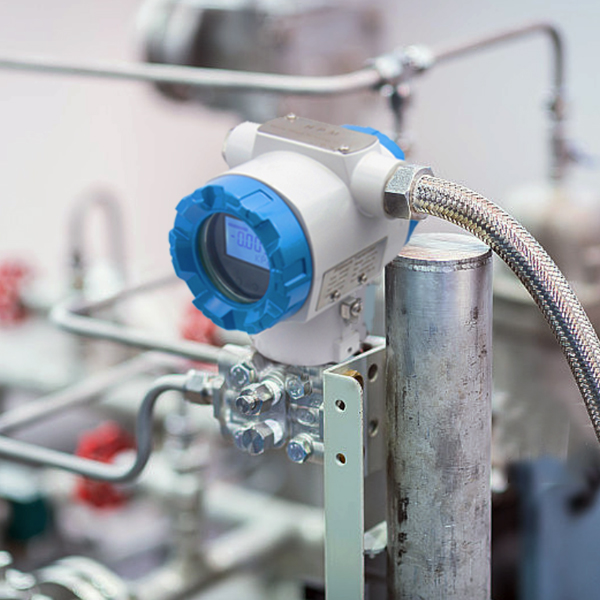

· Differential Pressure Transmitter

Differential pressure transmitters are common liquid level measurement instruments and are widely used in industrial liquid level monitoring. Its working principle is to calculate the liquid level height by measuring the pressure difference between the liquid surface and the bottom. This device is usually composed of two pressure sensors and a differential pressure transmitter, and can provide high-precision measurement results. Differential pressure transmitters are suitable for various liquid media, including corrosive liquids and high-temperature liquids, and have good durability and stability. Its advantage lies in the ability to conduct precise measurements in complex environments, making it particularly suitable for liquid level monitoring of equipment such as storage tanks and tanks. In addition, the maintenance cost of this equipment is relatively low, which can effectively reduce the operating costs of enterprises.

How to select those level instruments?

| Type | Advantage | Disadvantage | Disadvantage | Note |

| Differential Pressure Transmitter | High precision (±0.1% FS) Suitable for sealed containers Measurable interface and density | It requires a pressure guiding pipe and is prone to clogging or leakage Changes in medium density affect accuracy Complicated installation | Petroleum and chemical industry (high-temperature and high-pressure sealed containers) | Avoid viscous and crystalline media; The pressure guiding system needs to be maintained regularly |

| Submersible Level Transmitter | Easy to install and low cost Suitable for static pressure measurementQuick response | The sensor head needs to be immersed in the medium It is easily affected by the density of the medium Cables are prone to damage | Groundwater Wells, open containers (for non-corrosive liquids) | Not suitable for viscous or precipitating media |

| Magnetic Flap Liquid Level Meter | Intuitive display, no power supply required Simple structure and low maintenance Resistant to high pressure and high temperature | It needs to come into contact with media and is prone to contamination/corrosion Not suitable for slurries or viscous liquids Remote transmission requires additional configuration Accuracy not very high | Boilers and storage tanks (liquid level needs to be visually inspected on site) | The selection of materials should match the corrosiveness of the medium. Not suitable for remote transmission or environments without visible light |

| Radar Level Meter | Non-contact(80GHZ), corrosion-resistant High precision (±3mm) Not affected by temperature, pressure or steam | High cost | Large storage tanks, highly corrosive media (such as acids and alkalis | Pay attention to medium type and temperature |

| Ultrasonic Level Meter | Non-contact, easy to install | Measuring range <30m | Water treatment, open channels (clean liquid at normal temperature and pressure) | Avoid strong volatility or vacuum environments; The recommended measurement distance is less than 10 meters |

Related Certificate

ATEX, CNEX, ISO, and CE certificates for the differential pressure transmitter.

Summary

Discover More

Radar Level Meter

Usage Of Electromagnetic Flowmeter

Differential Pressure Sensor Case

Keep in touch with us

If you have any questions or requirements regarding liquid level sensor solutions, please feel free to contact our customer service team. Our professional team will provide you with detailed product information, answer your questions, and tailor the best solution to meet your needs.

Mob:+86-17551075580