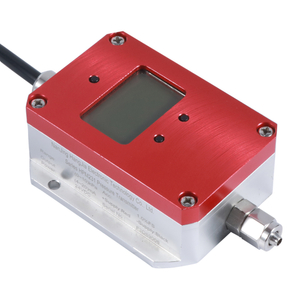

HPM320 Intelligent Lcd Display Differential Pressure Transmitter

| Availability: | |

|---|---|

| Quantity: | |

Overview

HPM320 Differential Pressure Transmitter adopts silicon piezoresistivedifferential pressure core. The process interface is all stainless steelstructure with strong corrosion resistance.The pressure interface is source nipple connection which is can be installed at the measuring piping orconnected through impulse piping. This product had standard voltage and current outputs and other options. It is easy installation, can be widely usedfor the measurement and control of differential pressure, liquid level and flow in the fields of process control, aerospace, automotive, medical equipment, HVAV, etc.

Features

316L stainless steel diaphragm isolation structure

Aluminium alloy protection shell, ingress protection IP65

Short-circuit protection and reverse polarity protectio

Impact resistance, anti-vibration and electromagmnetic compatibility resistanc

Customization according to requirement

Overview

HPM320 Differential Pressure Transmitter adopts silicon piezoresistivedifferential pressure core. The process interface is all stainless steelstructure with strong corrosion resistance.The pressure interface is source nipple connection which is can be installed at the measuring piping orconnected through impulse piping. This product had standard voltage and current outputs and other options. It is easy installation, can be widely usedfor the measurement and control of differential pressure, liquid level and flow in the fields of process control, aerospace, automotive, medical equipment, HVAV, etc.

Features

316L stainless steel diaphragm isolation structure

Aluminium alloy protection shell, ingress protection IP65

Short-circuit protection and reverse polarity protectio

Impact resistance, anti-vibration and electromagmnetic compatibility resistanc

Customization according to requirement

Measuring Medium | various liquid, gas compatible with 304 or 316L stainless steel |

Overload | 2x of full scale |

Accuracy | ±0.5%FS(std.) |

| Output Signal | 4~20mA, two wire; voltage |

| Power Supply | 24VDC(12~24VDC) |

Working Temperature | -30~85℃ |

| Electrical Connection | cable gland(M20*1.5) |

Measuring Medium | various liquid, gas compatible with 304 or 316L stainless steel |

Overload | 2x of full scale |

Accuracy | ±0.5%FS(std.) |

| Output Signal | 4~20mA, two wire; voltage |

| Power Supply | 24VDC(12~24VDC) |

Working Temperature | -30~85℃ |

| Electrical Connection | cable gland(M20*1.5) |

Overview

HPM320 Differential Pressure Transmitter adopts silicon piezoresistivedifferential pressure core. The process interface is all stainless steelstructure with strong corrosion resistance.The pressure interface is source nipple connection which is can be installed at the measuring piping orconnected through impulse piping. This product had standard voltage and current outputs and other options. It is easy installation, can be widely usedfor the measurement and control of differential pressure, liquid level and flow in the fields of process control, aerospace, automotive, medical equipment, HVAV, etc.

Features

316L stainless steel diaphragm isolation structure

Aluminium alloy protection shell, ingress protection IP65

Short-circuit protection and reverse polarity protectio

Impact resistance, anti-vibration and electromagmnetic compatibility resistanc

Customization according to requirement

Measuring Medium | various liquid, gas compatible with 304 or 316L stainless steel |

Overload | 2x of full scale |

Accuracy | ±0.5%FS(std.) |

| Output Signal | 4~20mA, two wire; voltage |

| Power Supply | 24VDC(12~24VDC) |

Working Temperature | -30~85℃ |

| Electrical Connection | cable gland(M20*1.5) |