Understanding Coolant Level Sensors: How They Work And Why They Matter

Views: 0 Author: Site Editor Publish Time: 2025-10-21 Origin: Site

In modern automotive and industrial machinery, engine health and efficient operation are critical. One of the key components that ensures this is the coolant system. Proper coolant levels maintain engine temperature, prevent overheating, and protect against long-term mechanical damage. At the heart of monitoring this system is the coolant level sensor, a small but essential device that informs operators about the status of the coolant system. This article explores how coolant level sensors work, their importance, types, installation considerations, and maintenance best practices.

1. What is a Coolant Level Sensor?

A coolant level sensor is a device designed to monitor the volume of coolant in a vehicle or machinery's reservoir. When coolant levels fall below a specified threshold, the sensor sends a signal to the vehicle’s dashboard or control system, alerting the driver or operator to take action. Without a functioning coolant level sensor, low coolant can go unnoticed, leading to engine overheating, reduced efficiency, and potential catastrophic failure.

In addition to automobiles, coolant level sensors are used in industrial equipment, generators, and heavy machinery, where maintaining precise coolant levels is critical for continuous operation and equipment longevity.

2. How Coolant Level Sensors Work

Coolant level sensors operate based on various detection principles, depending on the type and application. The fundamental goal is to detect whether the coolant is above or below a specific level and communicate this information reliably.

Float-Type Sensors

Float-type sensors are among the most common. They consist of a buoyant float attached to a mechanical arm or magnetic switch. As the coolant level rises or falls, the float moves accordingly:

When the coolant is sufficient, the float maintains a normal position, keeping the circuit open or closed.

When coolant drops below the threshold, the float triggers a switch, sending an alert to the operator.

This design is simple, reliable, and widely used in automotive and industrial applications.

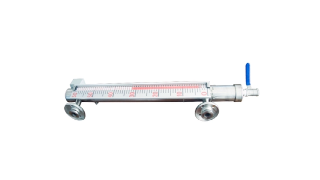

Resistive or Variable Resistance Sensors

Resistive sensors measure coolant levels using conductive elements or variable resistors. The sensor’s electrical resistance changes depending on the liquid level:

High coolant levels create a specific resistance reading.

Low coolant levels produce a different resistance, which is interpreted by the monitoring system.

This type of sensor provides continuous monitoring and can offer more precise readings than float-type sensors, making it suitable for complex systems requiring real-time data.

Capacitive Sensors

Capacitive sensors detect coolant levels by measuring changes in capacitance caused by the presence of liquid. As the coolant level rises, the dielectric constant of the sensing element changes, producing a measurable signal:

High levels increase capacitance.

Low levels decrease capacitance.

These sensors are non-contact and highly accurate, often used in industrial applications with corrosive or electrically conductive coolants.

Optical Sensors

Optical coolant sensors use light refraction or reflection to detect the presence of coolant:

A light beam is emitted across a sensing element.

When coolant is present, the light path changes, triggering a signal.

Optical sensors are precise and resistant to mechanical wear, making them ideal for harsh environments.

3. Why Coolant Level Sensors Are Important

Coolant level sensors play a vital role in protecting engines, machinery, and industrial systems from potential damage and operational inefficiencies. While often small and overlooked, these sensors provide critical information that allows operators to maintain proper coolant levels, safeguard components, and optimize system performance. Their importance can be highlighted across several key areas:

Preventing Overheating

One of the primary functions of coolant is to remove excess heat from engines or machinery. When coolant levels drop below the required threshold, the system’s ability to dissipate heat diminishes. This can result in severe consequences, including:

Engine block warping: Excessive heat can distort the engine block, leading to costly repairs or replacements.

Head gasket failure: Overheating can compromise the seal of the head gasket, causing leaks and reducing engine efficiency.

Reduced efficiency and fuel economy: Engines operating at higher-than-intended temperatures burn fuel less efficiently, increasing operational costs.

A coolant level sensor provides early warning when levels are low, enabling operators to take corrective action before these issues escalate, preventing costly damage and downtime.

Protecting Engine Components

Modern engines and machinery rely on precise thermal management to operate safely. Insufficient coolant can adversely affect multiple critical components, including:

Pistons and cylinders: Overheating can cause expansion and friction, leading to premature wear or seizing.

Radiators and hoses: Heat stress can damage radiator fins or weaken hose integrity, potentially causing leaks.

Water pumps and thermostats: Continuous overheating strains these components, reducing their lifespan and effectiveness.

By continuously monitoring coolant levels, sensors ensure that these components remain within safe operating temperatures, preventing mechanical failures and maintaining overall system reliability.

Maintaining System Efficiency

Coolant level sensors contribute to overall system efficiency by ensuring the cooling system operates optimally. Proper coolant levels allow effective heat transfer, prevent energy loss, and maintain consistent performance. Engines with accurate thermal regulation achieve better fuel economy, reduce emissions, and extend the life of internal components.

Safety Considerations

Low coolant levels can lead to sudden engine or machinery failure during operation, posing risks to operators, passengers, or surrounding equipment. By providing real-time alerts, coolant level sensors allow timely intervention, mitigating the risk of accidents, fire hazards, or extensive equipment damage.

In summary, coolant level sensors are essential not just for maintaining engine health, but also for enhancing operational efficiency, safety, and longevity of machinery. Their role in early detection and preventive maintenance makes them a cornerstone of modern engine and equipment management.

4. Applications of Coolant Level Sensors

Coolant level sensors are versatile and used across various sectors:

Automotive

In cars, trucks, and buses, sensors monitor radiator and reservoir levels, providing alerts on the dashboard. Modern vehicles integrate these sensors with the engine control unit (ECU) to adjust cooling fans, engine timing, and alert drivers.

Industrial Machinery

Heavy machinery and industrial equipment, including generators, compressors, and CNC machines, require precise coolant levels for heat regulation. Sensors ensure continuous operation and prevent downtime caused by overheating.

Marine Applications

Boats and ships rely on coolant systems for engines and onboard equipment. Sensors in marine engines monitor coolant levels despite movement, vibration, and corrosive seawater conditions.

Power Generation

Generators and turbines use coolant systems to maintain stable operating temperatures. Coolant level sensors protect these high-value systems, preventing costly shutdowns and maintaining power supply reliability.

5. Installation and Maintenance Considerations

Proper installation and regular maintenance are essential for accurate and reliable sensor performance.

Correct Placement

Sensors should be installed at locations where they can accurately detect coolant levels without being affected by turbulence, vibration, or air bubbles. Placement often depends on reservoir design and flow characteristics.

Compatibility with Coolant Types

Coolant can be water-based, glycol-based, or contain corrosion inhibitors. Sensors must be compatible with the chemical composition of the coolant to prevent corrosion or degradation over time.

Electrical Connections

Ensure secure and insulated wiring connections to avoid signal interference or short circuits. For automotive sensors, connections should withstand vibration and temperature fluctuations.

Regular Inspection

Inspect sensors periodically for corrosion, buildup, or physical damage. Clean float mechanisms, check resistive sensors for accurate readings, and test capacitive and optical sensors according to manufacturer guidelines.

Calibration

Some sensors, especially resistive or capacitive types, may require calibration to maintain accuracy over time. Calibration ensures reliable alerts and prevents false warnings.

6. Signs of Coolant Sensor Failure

Recognizing sensor issues early is critical. Common signs of failure include:

Dashboard warning lights activating incorrectly

Inconsistent or fluctuating coolant level readings

Engine overheating despite sufficient coolant

Physical damage to the sensor or wiring

Addressing sensor problems promptly can prevent engine damage and system inefficiency.

7. Advantages of Using Coolant Level Sensors

Using coolant level sensors provides multiple advantages:

Early Warning System

Sensors provide early alerts, allowing preventive maintenance before problems escalate.

Reduced Maintenance Costs

By preventing overheating and engine damage, sensors reduce repair and replacement costs.

Improved Reliability

Continuous monitoring ensures that engines and machinery operate efficiently and consistently.

Enhanced Safety

Sensors reduce the risk of sudden breakdowns, protecting operators and passengers.

Integration with Modern Systems

Many sensors can communicate with ECUs, industrial monitoring systems, and IoT platforms, enabling real-time monitoring and predictive maintenance.

8. Choosing the Right Coolant Level Sensor

When selecting a coolant level sensor, consider the following factors:

Type of Sensor: Float, resistive, capacitive, or optical

Compatibility: With coolant type and system materials

Operating Environment: Temperature, vibration, and exposure to chemicals

Signal Output: Analog or digital, depending on monitoring system requirements

Durability: Corrosion-resistant materials for long service life

Partnering with a reliable supplier ensures that the sensor meets technical specifications and provides long-term reliability.

9. Conclusion

Coolant level sensors are small but vital components in vehicles and industrial machinery. They provide continuous monitoring of coolant levels, ensuring engine efficiency, safety, and longevity. By alerting operators to low coolant levels, these sensors prevent overheating, mechanical damage, and system downtime.

For those seeking high-quality coolant level sensors, Nanjing Hangjia Electronic Technology Co., Ltd. offers a wide range of sensors designed for automotive, industrial, and marine applications. Their products combine reliability, precision, and durability, ensuring optimal performance across various systems. To learn more about their offerings or discuss specific requirements for your projects, you can contact Nanjing Hangjia Electronic Technology Co., Ltd. directly. Working with an experienced supplier ensures your equipment remains safe, efficient, and well-maintained.