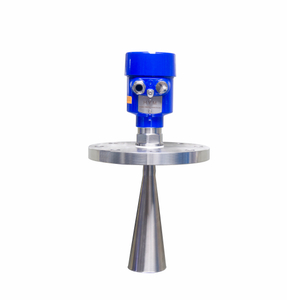

Non-contact G1'' NPT1'' SPDT DPDT Vibration Turning Fork Liquid Level Switch

| Availability: | |

|---|---|

| Quantity: | |

Overview

HYM610 Turning Fork Switch is a new-style level switch. The turning fork of sensor vibrates at its natural frequency. When the turning fork touches liquid or other mediums, its natural frequency reduces because the energy is consumes on the friction between particles to force the amplitude to decrease sharply then to stop. The change of frequency actives liquid level switch and creates in-off signals. This operating principle does not need massive mechanical motion with low driving power and adjustment free, it can start up quickly with low cost. It also has many advantages such as sample structure, no moving parts, maintenance free, no wearing, long operating life, flexibility and reliability. Turning fork switch can be used whenever the float level switch cannot be used due to the structure, turbulence, agitation, bubbles, vibration and other reasons. Turning fork witch is also called “electric float”. It has no switch moving parts, so there is no need for maintenance or adjustment. It is the upgraded product of float level switch. Turning fork level switch is widely used in the petrochemical, light industry, food, water treatment and other industries to alarm and control the upper and lower limit of the material level.

Application

Petrochemical

Light industry

Food industry

Water treatment

Other industries to alarm and control the upper and lower limit of the material level

Overview

HYM610 Turning Fork Switch is a new-style level switch. The turning fork of sensor vibrates at its natural frequency. When the turning fork touches liquid or other mediums, its natural frequency reduces because the energy is consumes on the friction between particles to force the amplitude to decrease sharply then to stop. The change of frequency actives liquid level switch and creates in-off signals. This operating principle does not need massive mechanical motion with low driving power and adjustment free, it can start up quickly with low cost. It also has many advantages such as sample structure, no moving parts, maintenance free, no wearing, long operating life, flexibility and reliability. Turning fork switch can be used whenever the float level switch cannot be used due to the structure, turbulence, agitation, bubbles, vibration and other reasons. Turning fork witch is also called “electric float”. It has no switch moving parts, so there is no need for maintenance or adjustment. It is the upgraded product of float level switch. Turning fork level switch is widely used in the petrochemical, light industry, food, water treatment and other industries to alarm and control the upper and lower limit of the material level.

Application

Petrochemical

Light industry

Food industry

Water treatment

Other industries to alarm and control the upper and lower limit of the material level

Features

Strong adaptation

The different electrical parameters and densities of measuring medium have no influence for the measurement. Scale formation, agitation, turbulence, bubbles, vibration, medium viscosity, high temperature and other terrible conditions also have no influence for the measurement.

Adjustment free

The measurement of limit switch of turning fork does not influenced by the electrical parameters and densities of measuring medium, therefore, there is no need to do field adjustment no matter what kind of liquid is measured.

Maintenance free

The measuring process of limit switch of turning fork is completed by electronic circuit, without any moving parts, therefore, there is no need to maintain once it is installed and put into use.

Features

Strong adaptation

The different electrical parameters and densities of measuring medium have no influence for the measurement. Scale formation, agitation, turbulence, bubbles, vibration, medium viscosity, high temperature and other terrible conditions also have no influence for the measurement.

Adjustment free

The measurement of limit switch of turning fork does not influenced by the electrical parameters and densities of measuring medium, therefore, there is no need to do field adjustment no matter what kind of liquid is measured.

Maintenance free

The measuring process of limit switch of turning fork is completed by electronic circuit, without any moving parts, therefore, there is no need to maintain once it is installed and put into use.

Supply Voltage | 24VDC or 220VAC |

Output Way | SPDT relay (single-pole double-throw) |

Ambient Temp | -20℃~70℃ |

Medium Temp | -40℃~150℃ |

Operation Pressure | Less than 2MPa |

Medium Density | Minimal 0.6g/cm3 |

Time-lapse | 1~50s(optional) |

High-low signal Alarm | It can be set as HLFS (high alarm) or LLFS (low alarm) |

Connection | 1”NPT or G thread, DN25 Flange can be customized |

Supply Voltage | 24VDC or 220VAC |

Output Way | SPDT relay (single-pole double-throw) |

Ambient Temp | -20℃~70℃ |

Medium Temp | -40℃~150℃ |

Operation Pressure | Less than 2MPa |

Medium Density | Minimal 0.6g/cm3 |

Time-lapse | 1~50s(optional) |

High-low signal Alarm | It can be set as HLFS (high alarm) or LLFS (low alarm) |

Connection | 1”NPT or G thread, DN25 Flange can be customized |

Overview

HYM610 Turning Fork Switch is a new-style level switch. The turning fork of sensor vibrates at its natural frequency. When the turning fork touches liquid or other mediums, its natural frequency reduces because the energy is consumes on the friction between particles to force the amplitude to decrease sharply then to stop. The change of frequency actives liquid level switch and creates in-off signals. This operating principle does not need massive mechanical motion with low driving power and adjustment free, it can start up quickly with low cost. It also has many advantages such as sample structure, no moving parts, maintenance free, no wearing, long operating life, flexibility and reliability. Turning fork switch can be used whenever the float level switch cannot be used due to the structure, turbulence, agitation, bubbles, vibration and other reasons. Turning fork witch is also called “electric float”. It has no switch moving parts, so there is no need for maintenance or adjustment. It is the upgraded product of float level switch. Turning fork level switch is widely used in the petrochemical, light industry, food, water treatment and other industries to alarm and control the upper and lower limit of the material level.

Application

Petrochemical

Light industry

Food industry

Water treatment

Other industries to alarm and control the upper and lower limit of the material level

Features

Strong adaptation

The different electrical parameters and densities of measuring medium have no influence for the measurement. Scale formation, agitation, turbulence, bubbles, vibration, medium viscosity, high temperature and other terrible conditions also have no influence for the measurement.

Adjustment free

The measurement of limit switch of turning fork does not influenced by the electrical parameters and densities of measuring medium, therefore, there is no need to do field adjustment no matter what kind of liquid is measured.

Maintenance free

The measuring process of limit switch of turning fork is completed by electronic circuit, without any moving parts, therefore, there is no need to maintain once it is installed and put into use.

Supply Voltage | 24VDC or 220VAC |

Output Way | SPDT relay (single-pole double-throw) |

Ambient Temp | -20℃~70℃ |

Medium Temp | -40℃~150℃ |

Operation Pressure | Less than 2MPa |

Medium Density | Minimal 0.6g/cm3 |

Time-lapse | 1~50s(optional) |

High-low signal Alarm | It can be set as HLFS (high alarm) or LLFS (low alarm) |

Connection | 1”NPT or G thread, DN25 Flange can be customized |