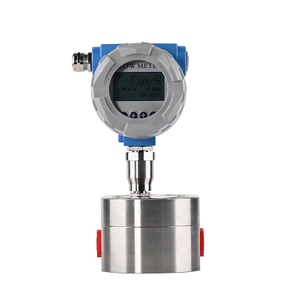

HFM200 Gas Liquid Steam Measurement DN15-DN300 Flange Vortex Flowmeter

| Availability: | |

|---|---|

| Quantity: | |

Overview

Introducing the HFM200 Vortex Flowmeter, a cutting-edge stress detection device that revolutionizes flow measurement. This innovative flowmeter utilizes a piezoelectric crystal as its measuring element, operating on the renowned Karmann vortex principle. The HFM200 offers a multitude of advantages that set it apart in the industry.

One of the key benefits of the HFM200 is its wide range rate capability, ensuring versatility in various flow conditions. Coupled with high accuracy and minimal pressure loss, this flowmeter delivers precise measurements without compromising on efficiency. Additionally, its exceptional medium versatility allows for seamless integration across different applications.

The HFM200 Vortex Flowmeter features a pulse signal output that is directly proportional to the flow rate, enabling easy data interpretation and analysis. Its user-friendly design facilitates straightforward connection with computer systems, enhancing data management and monitoring capabilities.

Notably, the HFM200 is engineered with a separate installation of the inspection probe and vortex generator, ensuring that the heat-resistant piezoelectric crystal remains isolated from the medium. This unique design not only simplifies the instrument's structure but also enhances its versatility and stability, making it a reliable choice for diverse industrial settings.

In conclusion, the HFM200 Vortex Flowmeter combines advanced technology with practical features to deliver accurate and efficient flow measurement solutions. Experience the benefits of its simple yet robust design, exceptional versatility, and high stability. Upgrade your flow measurement capabilities with the HFM200 Vortex Flowmeter today.

Application

Petroleum industry, natural gas

Chemical, metallurgical industry

Textile, paper industry

Saturated vapor, compressed air and general gases

Thermal metering, heating systems, thermal power plants and heat exchangers

Overview

Introducing the HFM200 Vortex Flowmeter, a cutting-edge stress detection device that revolutionizes flow measurement. This innovative flowmeter utilizes a piezoelectric crystal as its measuring element, operating on the renowned Karmann vortex principle. The HFM200 offers a multitude of advantages that set it apart in the industry.

One of the key benefits of the HFM200 is its wide range rate capability, ensuring versatility in various flow conditions. Coupled with high accuracy and minimal pressure loss, this flowmeter delivers precise measurements without compromising on efficiency. Additionally, its exceptional medium versatility allows for seamless integration across different applications.

The HFM200 Vortex Flowmeter features a pulse signal output that is directly proportional to the flow rate, enabling easy data interpretation and analysis. Its user-friendly design facilitates straightforward connection with computer systems, enhancing data management and monitoring capabilities.

Notably, the HFM200 is engineered with a separate installation of the inspection probe and vortex generator, ensuring that the heat-resistant piezoelectric crystal remains isolated from the medium. This unique design not only simplifies the instrument's structure but also enhances its versatility and stability, making it a reliable choice for diverse industrial settings.

In conclusion, the HFM200 Vortex Flowmeter combines advanced technology with practical features to deliver accurate and efficient flow measurement solutions. Experience the benefits of its simple yet robust design, exceptional versatility, and high stability. Upgrade your flow measurement capabilities with the HFM200 Vortex Flowmeter today.

Application

Petroleum industry, natural gas

Chemical, metallurgical industry

Textile, paper industry

Saturated vapor, compressed air and general gases

Thermal metering, heating systems, thermal power plants and heat exchangers

Clear LCD display screen, display instantaneous flow and cumulative flow respectively

High-strength piezoelectric crystal, integrated structure, impact resistance

Optional temperature compensation, pressure temperature, to meet more field services

The circuit board is processed through ageing before delivery, and it is with the real flow calibration for whole machine , more suitable for field use.

No external power supply is required. It adopts 3.6V lithium batter for power supply, which can continuously work more than two years, especially suitable for use in the field where the power supply is difficult to access.

Clear LCD display screen, display instantaneous flow and cumulative flow respectively

High-strength piezoelectric crystal, integrated structure, impact resistance

Optional temperature compensation, pressure temperature, to meet more field services

The circuit board is processed through ageing before delivery, and it is with the real flow calibration for whole machine , more suitable for field use.

No external power supply is required. It adopts 3.6V lithium batter for power supply, which can continuously work more than two years, especially suitable for use in the field where the power supply is difficult to access.

| Aperture Diameter (mm) | 15, 20, 25, 40, 50, 65, 80, 100, 125, 150, 200, 250, 300, (300~1000 plug in) |

| Nominal Pressure (MPa) | DN15-DN200 4.0(>4.0, negotiation ), DN250-DN300 1.6(>1.6,negotiation ) |

| Medium Temperature (℃) | Piezoelectric type: -40~150, -40~260, -40~330; capacitive type: -40~400, -40~500 (negotiation ) |

| Accuracy | ±1%,±1.5%; Plug in type: ±2.5% |

| Supply Voltage | Sensor: DC +12V, DC +24V; Transmitter: DC +12V , DC +24V; |

| Output Signal | Square-wave pulse(excluding battery powered) Current: 4~20mA |

| Environmental Conditions | Temperature: -20℃~55℃, Relative humidity: 5%~90%, Atmospheric pressure: 86~106kPa |

| Aperture Diameter (mm) | 15, 20, 25, 40, 50, 65, 80, 100, 125, 150, 200, 250, 300, (300~1000 plug in) |

| Nominal Pressure (MPa) | DN15-DN200 4.0(>4.0, negotiation ), DN250-DN300 1.6(>1.6,negotiation ) |

| Medium Temperature (℃) | Piezoelectric type: -40~150, -40~260, -40~330; capacitive type: -40~400, -40~500 (negotiation ) |

| Accuracy | ±1%,±1.5%; Plug in type: ±2.5% |

| Supply Voltage | Sensor: DC +12V, DC +24V; Transmitter: DC +12V , DC +24V; |

| Output Signal | Square-wave pulse(excluding battery powered) Current: 4~20mA |

| Environmental Conditions | Temperature: -20℃~55℃, Relative humidity: 5%~90%, Atmospheric pressure: 86~106kPa |

Overview

Introducing the HFM200 Vortex Flowmeter, a cutting-edge stress detection device that revolutionizes flow measurement. This innovative flowmeter utilizes a piezoelectric crystal as its measuring element, operating on the renowned Karmann vortex principle. The HFM200 offers a multitude of advantages that set it apart in the industry.

One of the key benefits of the HFM200 is its wide range rate capability, ensuring versatility in various flow conditions. Coupled with high accuracy and minimal pressure loss, this flowmeter delivers precise measurements without compromising on efficiency. Additionally, its exceptional medium versatility allows for seamless integration across different applications.

The HFM200 Vortex Flowmeter features a pulse signal output that is directly proportional to the flow rate, enabling easy data interpretation and analysis. Its user-friendly design facilitates straightforward connection with computer systems, enhancing data management and monitoring capabilities.

Notably, the HFM200 is engineered with a separate installation of the inspection probe and vortex generator, ensuring that the heat-resistant piezoelectric crystal remains isolated from the medium. This unique design not only simplifies the instrument's structure but also enhances its versatility and stability, making it a reliable choice for diverse industrial settings.

In conclusion, the HFM200 Vortex Flowmeter combines advanced technology with practical features to deliver accurate and efficient flow measurement solutions. Experience the benefits of its simple yet robust design, exceptional versatility, and high stability. Upgrade your flow measurement capabilities with the HFM200 Vortex Flowmeter today.

Application

Petroleum industry, natural gas

Chemical, metallurgical industry

Textile, paper industry

Saturated vapor, compressed air and general gases

Thermal metering, heating systems, thermal power plants and heat exchangers

Clear LCD display screen, display instantaneous flow and cumulative flow respectively

High-strength piezoelectric crystal, integrated structure, impact resistance

Optional temperature compensation, pressure temperature, to meet more field services

The circuit board is processed through ageing before delivery, and it is with the real flow calibration for whole machine , more suitable for field use.

No external power supply is required. It adopts 3.6V lithium batter for power supply, which can continuously work more than two years, especially suitable for use in the field where the power supply is difficult to access.

| Aperture Diameter (mm) | 15, 20, 25, 40, 50, 65, 80, 100, 125, 150, 200, 250, 300, (300~1000 plug in) |

| Nominal Pressure (MPa) | DN15-DN200 4.0(>4.0, negotiation ), DN250-DN300 1.6(>1.6,negotiation ) |

| Medium Temperature (℃) | Piezoelectric type: -40~150, -40~260, -40~330; capacitive type: -40~400, -40~500 (negotiation ) |

| Accuracy | ±1%,±1.5%; Plug in type: ±2.5% |

| Supply Voltage | Sensor: DC +12V, DC +24V; Transmitter: DC +12V , DC +24V; |

| Output Signal | Square-wave pulse(excluding battery powered) Current: 4~20mA |

| Environmental Conditions | Temperature: -20℃~55℃, Relative humidity: 5%~90%, Atmospheric pressure: 86~106kPa |